History, Technology, and Future Prospects

As the automotive industry pushes toward sustainable alternatives to fossil fuels, hydrogen has emerged as a promising energy source. While hydrogen fuel cells often dominate discussions, hydrogen internal combustion engines (H2-ICE) present another viable pathway. Haush explores the history, technology, challenges, and future of hydrogen-powered internal combustion engines, highlighting companies investing in this alternative propulsion system.

History

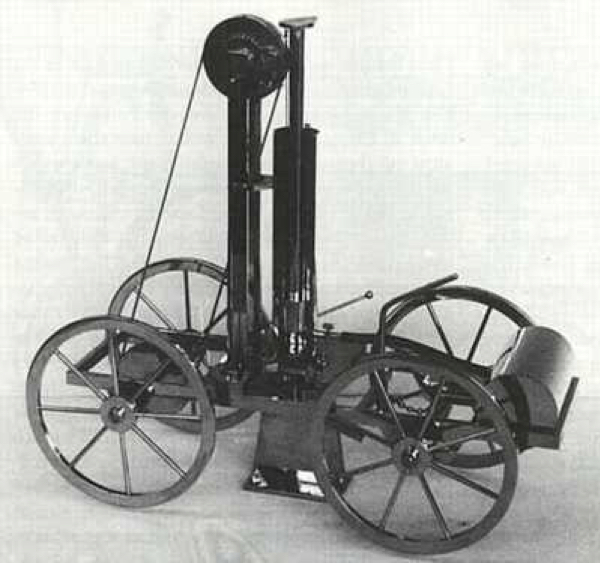

The concept of burning hydrogen in an internal combustion engine dates back to the early 19th century. The first recorded experiment with hydrogen as a fuel occurred in 1807 when François Isaac de Rivaz built an engine powered by a hydrogen-oxygen mixture. However, practical applications remained limited due to technological constraints.

In the 20th century, hydrogen ICEs gained attention during periods of oil crises. During World War II, some researchers experimented with hydrogen as an alternative fuel. In the 1970s and 1980s, amid growing concerns over fuel shortages and emissions, BMW developed a hydrogen-powered version of its 7-Series, known as the BMW Hydrogen 7, though it never reached mass production.

How Hydrogen ICE Technology Works

Hydrogen ICEs operate similarly to conventional gasoline engines, utilizing spark ignition to combust hydrogen. The key differences lie in the combustion process and fuel storage:

-

Fuel Injection:

Hydrogen can be directly injected into the combustion chamber (direct injection) or premixed with air before combustion (port injection).

-

Higher Efficiency:

Hydrogen has a faster flame speed than gasoline, which can improve combustion efficiency.

-

Lower Emissions:

Hydrogen combustion primarily produces water vapour, although small amounts of NOx (nitrogen oxides) can form due to high combustion temperatures.

Challenges of Hydrogen ICE Technology

While H2-ICEs offer several benefits, they also present technical challenges:

-

1. Hydrogen Embrittlement:

Hydrogen molecules can diffuse into metals, causing brittleness and leading to material degradation over time. Engine components, especially valves and cylinder walls, must be specially designed to resist this effect.

-

2. High Combustion Temperatures:

Hydrogen burns hotter than gasoline, increasing the risk of NOx emissions. Advanced cooling and exhaust treatment systems are required to mitigate this.

-

3. Lower Energy Density:

Hydrogen has a lower volumetric energy density than gasoline or diesel, requiring high-pressure storage (typically at 350-700 bar) or cryogenic solutions.

-

4. Backfire and Pre-ignition:

Hydrogen’s high reactivity can cause backfire issues in port injection designs, necessitating careful fuel-air mixture control.

Companies Developing Hydrogen ICE Vehicles

-

Toyota

Toyota is one of the leading companies investing in hydrogen ICE technology. The company has tested hydrogen-powered versions of its Corolla race cars in Japan’s Super Taikyu endurance series, using a modified 1.6L turbocharged three-cylinder engine. Toyota believes hydrogen ICEs can provide a more familiar driving experience than fuel cells while reducing CO2 emissions.

-

Yamaha

In collaboration with Toyota, Yamaha has developed a 5.0L V8 hydrogen engine based on the Lexus RC F’s gasoline engine. The company aims to bring hydrogen-powered performance vehicles to market in the coming years.

-

Kawasaki Heavy Industries

Kawasaki is exploring hydrogen ICE technology for industrial applications, including motorcycles and small off-road vehicles. The company is also working on hydrogen infrastructure, such as the Suiso Frontier, the world’s first liquefied hydrogen carrier.

-

Cummins

Cummins, a global leader in heavy-duty engines, is developing hydrogen-powered internal combustion engines for commercial trucks. The company has introduced a 15-liter hydrogen engine, targeting applications in freight transport and heavy machinery.

-

JCB

British equipment manufacturer JCB has built hydrogen ICEs for construction and agricultural machinery. The company has already produced prototypes of hydrogen-powered backhoes and loaders, demonstrating the feasibility of hydrogen in off-highway applications.

-

Bosch

Bosch is investing heavily in hydrogen ICE components, including injectors, control systems, and exhaust treatment technologies. The company sees potential in retrofitting existing diesel engines to run on hydrogen, particularly in heavy-duty transport.

Innovations in Hydrogen ICE Technology

Recent advancements aim to address the challenges of hydrogen combustion:

-

Water Injection:

Some manufacturers, like Toyota, are exploring water injection systems to lower combustion temperatures and reduce NOx emissions.

-

Advanced Materials:

New metal alloys and coatings are being developed to prevent hydrogen embrittlement in engine components.

-

High-Pressure Direct Injection:

Direct injection at ultra-high pressures helps prevent backfire and improves combustion efficiency.

-

Hybridization:

Some companies are pairing hydrogen ICEs with electric motors in hybrid configurations to optimize fuel economy and performance.

The Future of Hydrogen ICE Technology

Several companies plan to expand their hydrogen ICE research and development:

-

Toyota and Yamaha

aim to commercialise hydrogen-powered sports cars and motorcycles within the next decade.

-

Cummins and Daimler

are working on hydrogen ICE solutions for long-haul trucking.

-

JCB

plans to mass-produce hydrogen-powered construction equipment by 2030.

-

Bosch

is pushing for hydrogen ICE adoption in both automotive and industrial applications.

While hydrogen fuel cells remain a strong competitor, H2-ICEs offer advantages such as lower production costs and compatibility with existing engine architectures. Retrofitting diesel engines to run on hydrogen could provide a transitional solution for industries seeking to decarbonize without fully shifting to electrification.

Hydrogen ICE a Reality Today

Hydrogen internal combustion engines represent a promising alternative to traditional fuels, offering a pathway to reduced carbon emissions while leveraging existing ICE infrastructure. Despite challenges such as hydrogen embrittlement and high combustion temperatures, continuous advancements in materials, fuel injection, and cooling systems are making hydrogen ICEs more viable.

With major companies like Toyota, Yamaha, Cummins, and JCB actively investing in the technology, hydrogen ICEs could become a significant part of the transportation sector’s transition toward a cleaner future. While full-scale adoption remains uncertain, these engines could serve as a bridge between fossil fuels and fully electric propulsion systems, particularly in heavy-duty and off-highway applications.

The race for sustainable mobility is far from over, and hydrogen internal combustion engines may yet play a crucial role in shaping the future of transportation.

The post Hydrogen Internal Combustion Engines first appeared on Haush.